Almost all modern vehicles since the late 60’s that run on gasoline use a charcoal fuel vapor venting system. Put simply, vapors from the fuel tank are run to a charcoal canister, typically found in the engine compartment, that absorbs the vapors. When the engine is running and at certain times the vapors are pulled into the engine through the purge port and burned off.

It’s common practice (even though it’s pretty much wrong) to remove much of this equipment. Often because it’s defective from age or it’s misunderstood. Some people see it as power robbing emissions equipment, but the venting system is not. Removing this equipment can cause the fuel tank to vent into the air which is bad enough but often the venting to air creates a smelly garage. Often the biggest issue with improper venting is slow fuel tank filling. If the pump keeps kicking off you may have improper venting.

DIY Retrofitting the Charcoal System

Retrofitting an old vehicle to use this system can be tricky but we learned of a rather simple and effective method that’s commonly used in the street rod/classic car world. This may or may not be legal in your area so guide yourself accordingly.

Non-Vacuum Venting

This is the simplest method uses a charcoal canister but no vacuum purge to the engine. This will remove odors but can cause the need to change charcoal from time to time. Basically the vents from the tank are attached to the charcoal canister and the tank is left to vent to the air through the charcoal.

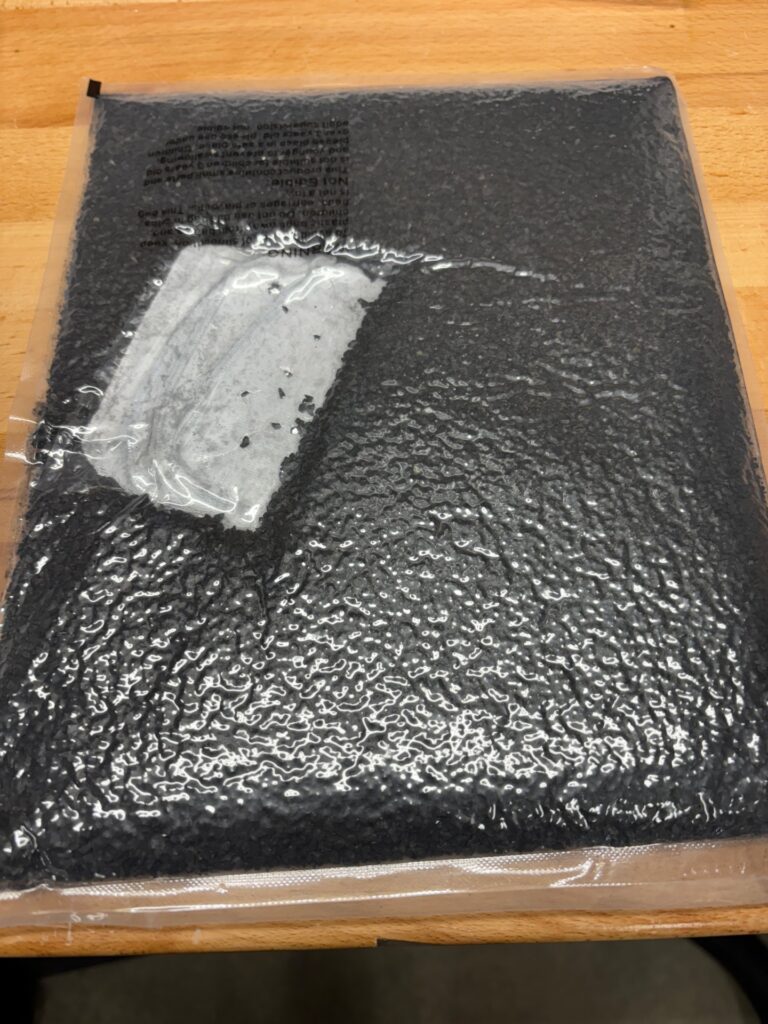

The DIY method of this uses a few parts, most you can get from a home supply store. We used some 1.5″ PVC along with a 1.5″ PVC Clamp. Some steel wool, fuel hose and clamps, along with a fitting or two and some activated charcoal commonly used in a fish tank.

The lower cap of the canister is drilled out with some small holes for venting then glued to the pipe section. The other side gets the threaded fitting glued to it ready for the threaded cap. The threaded cap needs a hole drilled in it to install a fitting for the hose that comes from the tank. Usually this would go to the tank’s rollover valve.

We mounted the canister in the rear wheel well with the new rollover valve. The rollover valve is attached to the 2 breather outlets on the tank and the top of the rollover valve connects to the charcoal canister. The tank breathes in and out through the charcoal. A plate was fabricated to protect the canister from wheel debris and water. The jeepfan.com CJ has a fiberglass body which doesn’t have a separator at the rear of the wheel well.

So far there’s been no noticeable smell of fuel from the Jeep. Someday we may route a vacuum line to the engine to incorporate a purge from the canister for better venting when the engine is running. This can be tricky since a specific valve (or valves) is needed to enable or disable the flow to the engine. The valve being open constantly would essentially be a vacuum leak.

This project was part of a larger project for the CJ, we installed a Holley Sniper 2 fuel injection system. Take a look.