I’ve suffered through years of a junky welders. The first welder was an old Lincoln stick welder that was ok except for the fact that it was stick and the second was Craftsman 110 MIG welder. I am far from a good welder but these junky welders made me even worse. I’d often just tack items and bribe a friend to complete a job with their welder for me.

For years I’ve debated getting a new welder but I didn’t really do enough work to justify the expense but the time finally came. I did quite a bit of online research on welders and there are many that fall within my needs. I wanted an inverter style MIG that ran on 220v, small in size and powerful enough to do the work I do. Like most of us we are looking for value while maintaining some level of quality.

BTW, jeepfan.com has no affiliation with Harbor Freight.

My research led me to the Titanium brand from Harbor Freight. This line of welders rates extremely well for hobbyist welders like me and the Titanium MIG 170 model fit exactly what I needed. The welder is an excellent price, much lower than higher end competitors. If you are a member of the HF Inside Track club and you have patience you can get 25-30% off the regular price during special sales.

Titanium MIG 170 Specs

- Inverter technology

- 24 lbs

- Dual voltage capable

- MIG or flux-core capable

- 30-170A output

- Digital display

Unboxing

Let’s dig in to this thing.

The welder is nicely packaged and comes with almost everything you will need to get started. If you are using the MIG function you will need an Argon/CO2 tank and welding wire. I already had a tank which fit directly up to the regulator that the welder came with.

Picking Welding Wire

Most of the welding I do is in the 1/8″ to 1/4″ range. Using the chart within the side door of the welder you can determine the size wire you will need for the job. It indicated that the best selection is .030 solid core wire.

The chart shown inside the welder is extremely handy since it contains many of the settings you will need during welder use. Remember it is there.

Getting the Welder Set Up

I had a home made cart for the welder that was made years ago and the new welder fit perfectly on it. The gas bottle was already there and ready to be hooked up to the new regulator.

The new regulator was attached to the tank and the gas feed line was attached to the welder. The gun and ground wires needed to be attached to the front. Be sure to attach the ground in the proper setting for your intended use.

New Garage = No Welder Outlet

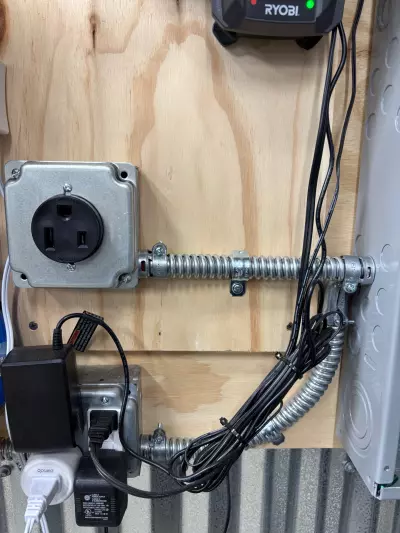

You may know that the jeepfan.com Jeeps are enjoying their new home in our new garage. But the new garage wasn’t equipped with an outlet to plug in the welder to. Luckily there is a nearby electrician that can get a proper NEMA 6-50 plug installed and we can get welding. I won’t go through the steps of installation of the plug and I’d recommend consulting an electrician. I decided that the plug would go near the circuit panel box for a quick and easy install.

Testing out the Titanium MIG 170 Welder

Now that there is power the solid core welding wire was installed into the welder and it was powered on. I set the settings to the kind of steel I was welding and let it rip. It felt near effortless and the flow of the wire and power seemed great. Maybe there is a welder in me after all.

Welder Extension Cord

You realize quickly that no matter the location of the welder outlet you are often too far away for the standard cord that is attached to the welder to reach. A 25 foot welder extension cord was picked up to solve this problem. This particular cord from Parkworld has 8 gauge wire and proper plugs to ensure safe and loss free use. In addition there is a nice storage/carry strap to keep the cord neat when not in use.

Wrapping it all Up

The new Harbor Freight Titanium 170 welder is all ready to go for our next Jeep project. Taking some time to practice will really make your welds so much better. Get a good helmet and remember to turn off the gas when it’s not being used.